Mining operations often involve working with media containing slurry particles, which can be challenging due to the harsh and abrasive nature of these mixtures. Understanding the various types of slurries and their characteristics is essential when choosing sealing solutions.

Understanding Slurries in Mining

Slurries in mining can be broadly categorized based on their settling characteristics.

‘Settling’ slurries, which settle quickly, tend to be more abrasive.

In contrast, ‘non-settling’ slurries remain suspended for longer and are typically less abrasive but due to smaller particles size can have an impact on the mechanical seal faces.

There’s also ‘dewatering’ slurry that consists of lighter organic materials and has a tendency to clog parts of the mechanical seal like the springs and cause inability of springs to perform as intented.

Different types of slurries are used in various applications, including alumina, nickel, and copper applications, each presenting its unique challenges. The type of slurry, particle sharpness, particle size, and slurry hardness are critical factors to consider when selecting sealing solutions.

Chesterton’s 170 Mechanical Seal : A Seal Designed for Harsh Slurry Environments

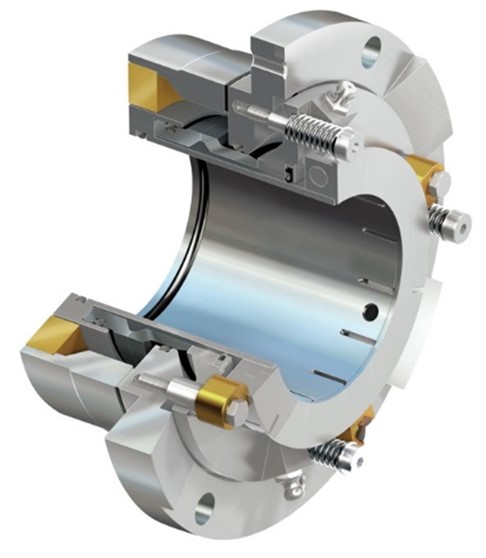

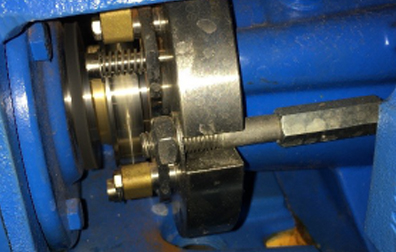

Chesterton’s 170 Slurry Cartridge Seal stands out as an innovative solution designed specifically for harsh, heavy consistency slurry environments. This seal eliminates the need for external flushes in most applications, simplifying the process, reducing potential issues and driving operational cost down.

The 170 Slurry Cartridge Seal can handle high solids content, making it ideal for dealing with the rigorous demands of mining operations. It can employ SpiralTrac™ technology, enhancing reliability and ensuring optimal performance even in challenging conditions.

Chesterton 170 Slurry Single Cartridge Seal

Designed to Extend the Life of Slurry Pumps

- Designed for heavy, high-solids slurry sealing

- Non-clog design enhances seal reliability

- Innovative pressure plate system keeps the springs entirely outside the seal

- Field repairable

Conclusion

In the demanding world of mining, choosing the right sealing solution is critical.

The Chesterton 170 Slurry Cartridge Seal is helping mining operations navigate the complex challenges presented by different slurry types, improving efficiency requirements and enhancing reliability in the process.

Please ask our Expert Desk for further information.

You can also make a preliminary selection using our product selector. Our product consultants will gladly assist you in selecting the ideal product for your application.